Overview

BL17-2 is a high-brightness, in-vacuum undulator (IVU) hard x-ray beamline (~ 5-18keV) optimized for materials scattering applications.

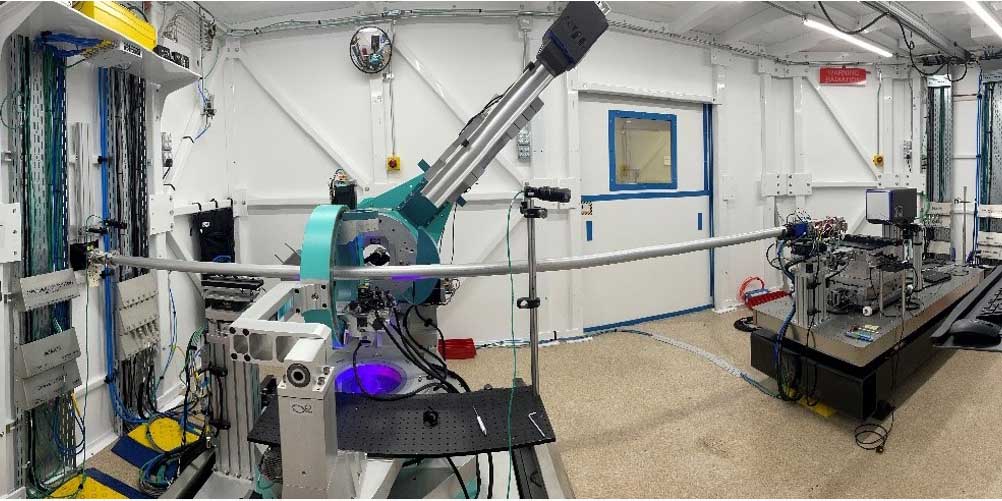

The beamline includes a nitrogen-cooled double crystal monochromator with multilayer capability for enhanced flux. Currently it offers Wide-Angle X-ray Scattering (WAXS) and X-ray diffraction (XRD) capabilities with a 6-circle diffractometer and cryocooler as well as a back table for custom setups including motorized stages for spatial mapping, secondary KB optics for micro-focused beam, and operando/in situ setups. Equipped with multiple configurable area detectors (Pilatus 100K/300K, Eiger 1M, Eiger 2 500k, Eiger 4M) and a Vortex Si drift detector for X-ray fluorescence, it facilitates real-time studies of materials processing, interfaces, and reactions. BL17-2 is optimized for investigating materials used in sustainable energy applications, enabling the characterization of buried interfaces and nanomaterials under operational conditions. The beamline supports time-domain research and studies requiring high flux, benefiting from the multilayer capability integrated into the monochromator. In the future, it will include the capability to perform simultaneous Small-Angle X-ray Scattering (SAXS)/WAXS and optical pump x-ray probe measurements using a planned Tangerine laser system.

This instrument supports a broad array of topics in material science, chemistry, physics, and environmental science. Notable applications include structural characterization of:

- Sustainable Energy Materials: Study materials for energy applications, focusing on interfaces.

- In-situ/Operando Studies: Observe materials processing and reactions in real-time.

- Interface Science: Characterize buried interfaces in materials at the atomic level.

- Catalysis Research: Study nanomaterial catalysts under operating conditions.

- Quantum Materials: Determine the structure of advanced electronic materials and interfaces.

- Time-Resolved Studies: Investigate dynamic processes with high time resolution.

in situ / operando measurements can be performed with facility supported or user provided sample environments. Contact the beam line scientist or engineer to discuss the feasibility of user provided sample environments.

Status —

Beamline Parameters —

| Energy Range | Resolution ΔE/E | Spot Size | Flux | Angular Acceptance | |

|---|---|---|---|---|---|

| Unfocused | 4000- 22000 eV | ~5 x 10-4 | ~10 x 50 um2 (Focused - front table) 15 x 90 um2 (Focused - back table) |

- | 1.5 mrad |

Optics —

| Monochromator | Energy Range (eV) | Resolution ΔE/E | Flux (Ph/s) |

|---|---|---|---|

| Si (111) | 4800-18200 | 1 x 10-4 | 2 x 1013 |

| Si (311) | 4800-18200 | 3 x 10-5 | 5 x 1012 |

| Multilayer | 7000 - 12000 | 1 x 10-3 | 2 x 1014 |

Source —

Instrumentation —

| Detectors | Pilatus 100K/300K with 172 µm × 172 µm pixel size, variable working distances |

|---|---|

| Eiger 1M, Eiger 4M, Eiger 2 500K with 75 µm × 75 µm pixel size | |

| Vortex®-EX silicon drift detector for XRF available for transmission geometries and GI without helium chamber | |

| Other (available upon request) | CryoCon 24C temperature controller with Sorensen DLM 40-15 external power supply |

| Keithley 2601B source meter | |

| BioLogic MPG200 potentiostat | |

| Oxford Cryojet |

Sample Environment —

| Cold Stage | ARS LT3-110 Cryostat with motorized sample stages, Temperature Range: 5K - 350K |

|---|---|

| GIXRD helium chamber | 21.5 mm × 20.5 mm Al sample stage with vacuum port, heating up to 200 °C |

| Standard GIXRD | 21.5 mm × 20.5 mm Al sample stage with vacuum port |

| Transmission plates | Multiple sample plates available with varying array and aperture sizes |

| Capillary heating | heating powders up to 500 °C, compatible with capillaries with 0.5-1.25 mm o.d. |

| Through staff collaboration | Capillary heating cell with gas dosing, static pressure (1.3 x 10-7 to 200 bar), mass flow control (10, 100, 200, 500, 1000 sccm), cooling down to 120 K, contact Nicholas Strange (nstrange@slac.stanford.edu) |

| Electrochemical cycling with up to 4 pouch cells, requires consult on cell specs, contact Molleigh Preefer (molleigh@slac.stanford.edu) |

Publications

Publications

Highlights

Science Highlights

We are in the process of porting over science highlights from our previous system. You can access new highlights and a portion or our catalog here.

For science highlights dated before 2021 visit this site. Use the filters to narrow down your search by year and beam line.