Scientists and engineers are interested in understanding how to improve the safety and strength of additively manufactured (3D printed) metal parts. Due to their low cost and design flexibility, additively manufactured metal parts are seeing increased use in real-world applications and understanding their limitations is important. To help understand what is happening during the build process, scientists at three national laboratories; SLAC National Accelerator Laboratory, Lawrence Livermore National Laboratory and Ames National Laboratory; developed a modified 3D printer to observe the build process using high-powered x-rays.

While there are several methods to build components, researchers focused on one of the more popular techniques, known as laser powder bed fusion (LPBF) additive manufacturing. This technique builds its components layer-by-layer using a high-power laser where each layer of metal powder is melted, and fused to the previous layer. The laser quickly rasters over the sample, where the powder is subjected to extreme conditions as it rapidly melts and solidifies. It is here in that researchers are trying to understand how build conditions, such as the laser power and speed, affect the melt pool and the final build conditions in titanium alloy components.

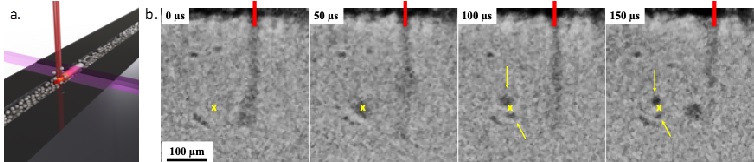

Combining the expertise of the multiple national laboratories, a specialty build system was developed to mimic the conditions in commercials LPBF systems (Figure 1a). This build system was specifically modified to be used in experiments at SSRL where high-powered x‑rays are used to observe the build process. X-rays are able to penetrate through the metal part to see processes that were previously hidden when using other more surface sensitive techniques. High-speed x-ray images were collected at rates as high as 20,000 frames per second so researchers observe the build process on time scales that are relevant to heating and cooling rates in the system. This is essential to help inform computer simulations that need experimental validation for their models.

With these high frame rates, it is possible to directly observe the effects of the laser beam moving across the part and the effect that it has on the material. This allows researchers to explore changing the laser parameters such as scan speed and power to quickly study their effects on the build quality. These parameters are important: with too little energy the metal will not melt, with too much energy a vapor-filled depression can be formed and voids left in the final part.

Researchers were able to study a subset of laser powers and speeds to consider how they affect the melt pool, vapor depression, and the dynamics of bubbles that are formed during the build process. One unique observation was how the bubbles were unstable in the melt pool and single bubbles can be seen splitting into multiple bubbles during the build (Figure 1b). Even then, once the part is solidified and the bubble is encapsulated in the final part, it is extremely difficult to remove that void without introducing additional voids.

While these first experiments were limited to titanium alloys, the system provides the flexibility to study many additional parameters and alloys. Additional studies will consider new materials, such as aluminum alloys, and specific build strategies to help eliminate the formation of the bubble defects. This work and instrument will help inform researchers understand the build process for metal components and design safe and reliable parts.

A. M. Kiss, A. Y. Fong, N. P. Calta, V. Thampy, A. A. Martin, P. J. Depond, J. Wang, M. J. Matthews, R. T. Ott, C. J. Tassone, K. H. Stone, M. J. Kramer, A. van Buuren, M. F. Toney and J. N. Weker, "Laser-induced Keyhole Defect Dynamics during Metal Additive Manufacturing", Adv. Eng. Mater. 21, 1900455 (2019) doi: 10.1002/adem.201900455