Today's laptop computers utilize flat panel displays where the light transmission from the back to the front of the display is modulated by orientation changes in liquid crystal (LC) molecules. Details are discussed in Ref. 2 below. One of the key steps in the manufacture of the displays is the alignment of the LC molecules in the display. Today this is done by mechanical rubbing of two polymer surfaces and then sandwiching the LC between two such surfaces with orthogonal rubbing directions. Over the past years a great challenge of this $20 billion/year industry has been to devise an alternative method of liquid crystal alignment. The rubbing process is plagued with contamination issues and the polymer film is deposited by a wet process that is incompatible with high-tech manufacturing techniques. Also, the rubbing process does not lend itself to the manufacture of multidomain alignment layers that are necessary to increase the limited viewing angle in present displays. The development of a new alignment technology, however, has been impeded by the fact that the origin of LC alignment has remained a mystery since its discovery in 1907.

Today's laptop computers utilize flat panel displays where the light transmission from the back to the front of the display is modulated by orientation changes in liquid crystal (LC) molecules. Details are discussed in Ref. 2 below. One of the key steps in the manufacture of the displays is the alignment of the LC molecules in the display. Today this is done by mechanical rubbing of two polymer surfaces and then sandwiching the LC between two such surfaces with orthogonal rubbing directions. Over the past years a great challenge of this $20 billion/year industry has been to devise an alternative method of liquid crystal alignment. The rubbing process is plagued with contamination issues and the polymer film is deposited by a wet process that is incompatible with high-tech manufacturing techniques. Also, the rubbing process does not lend itself to the manufacture of multidomain alignment layers that are necessary to increase the limited viewing angle in present displays. The development of a new alignment technology, however, has been impeded by the fact that the origin of LC alignment has remained a mystery since its discovery in 1907.

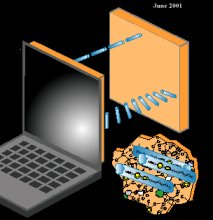

Polarization and surface sensitive NEXAFS spectroscopy measurements at SSRL have been used to solve this puzzle. The understanding of the molecular alignment mechanism for rubbed polymer surfaces (Refs. 1 and 2) has directly led to a proposal for the development of alternative alignment materials and processes which are discussed in the three patents listed below and described in Ref. 3 that was published in the June 22, 2001 issue of Science. The work has only recently been cleared for publication by IBM. The new proposed alignment material is an amorphous carbon film that can conveniently be deposited in a dry deposition process. Hydrogen is added in the deposition process to make it more transparent. Irradiation by a directional ion beam is used to create orientational order at the surface of the carbon film. The understanding of the alignment mechanism based on the creation of preferential molecular orientation in any carbonaceous material, including rubbing of polymer films or ion beam irradiation of carbon films, and the easy manufacturability of thin amorphous carbon layers by CVD or sputtering methods, convinced IBM to develop this process for manufacturing. The process has now cleared all development checkpoints and full flat panels have been reliably manufactured. The process is especially well suited for large displays and IBM has used it to build the highest resolution flat panels available today. The work on flat panel manufacturing was published in the May 3, 2001 issue of Nature.

Patents

- Dry Processing for Liquid-Crystal Displays using Atomic Beam Alignment (US #6020946)

- Alignment of Liquid Crystal Layers (US #6061114)

- Method of producing a multi-domain alignment layer by bombarding ions of normal incidence". (US #6061115)

- J. Stöhr, M. G. Samant, A. Cossy-Favre, J. Diaz, Y. Momoi, S. Odahara, and T. Nagata "Microscopic Origin of Liquid Crystal Alignment on Buffed Polymer Surfaces", Macromolecules 31, 1942 (1998)

- J. Stöhr and M. G. Samant "Liquid Crystal Alignment by Rubbed Polymer Surfaces: A Microscopic Bond Orientation Model", J. Electron Spectrosc. Rel. Phenom. 98-99, 189 (1999)

- J. Stöhr, M. G. Samant, J. Lüning, A. C. Callegari, P. Chaudhari, J. A. Doyle, J. A. Lacey, S. A. Lien, S. Purushothaman and J. L. Speidell, "Liquid Crystal Alignment on Carbonaceous Surfaces with Orientational Order", Science 292, 2299 (2001)

- P. Chaudhari, et al., "Atomic Beam Alignment of Inorganic Materials for Liquid Crystal Displays", Nature