As the dimension of the microelectronic devices keep shrinking there is a press ing need to increase the dielectric constant of the gate oxide. Fabrication of the gate oxide out of ferroelectric nanostructure provides a possible solution. However, new approaches to the fabrication of ferroelectric nanostructures onto substrates are needed before nanoscale ferroelectrics can be successfully integrated into functional microelectronic devices. An important challenge is that the Sol fabrication of these materials in organized arrangement of the nanostructures is reliable and very cost-effective.

In the literature two methods for fabrication of ferroelectric nanostructures have been reported; top-down, i.e., lithography-based patterning and a bottom-up approach based on self-assembly. The first approach provides good spatial resolution and positioning precision, but at present is very expensive. A further limitation of this approach is that fabricated structures cannot be easily made much smaller than ~100 nm laterally. Bottom-up methods are low-cost and allow a relatively easy fabrication of structures with sizes below 100 nm, but the issues of organization and homogeneous size distribution of the nanostructures have not been fully solved.

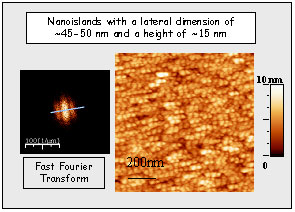

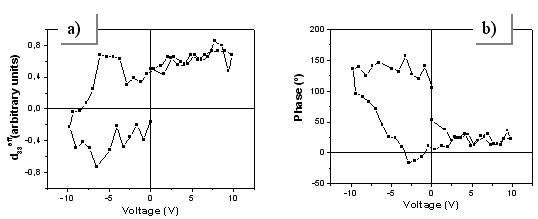

In this work a novel bottom-up preparation method for the fabrication of ferroelectric nanostructures onto SrTiO3 single crystal substrates is reported. It involves the use of microemulsions, sol-gel chemistry and chemical solution deposition. A transparent solution was first prepared by mixing a PbTiO3 precursor sol and a microemulsion formed by water, cyclohexane and the surfactant Brij 30 (Polyoxyethylene(4) lauryl ether). The solution was deposited onto the substrates by spin-coating and dried under controlled conditions. After a rapid thermal treatment of crystallization at 650ºC, nanostructures with uniform sizes of ~40 nm diameter and showing periodicity in some zones of the substrate were obtained (Fig.1). In order to ensure that the fabricated nanostructures were ferroelectric, measurements were carried out on them by Piezoresponse Force Microscopy (PFM). For this, samples were deposited onto conductive Nb-doped (100)SrTiO3 substrates. Local piezoelectric and phase hysteresis loops were measured in the regions of the coating where the ~40 nm diameter particles showed an order (Fig.2).

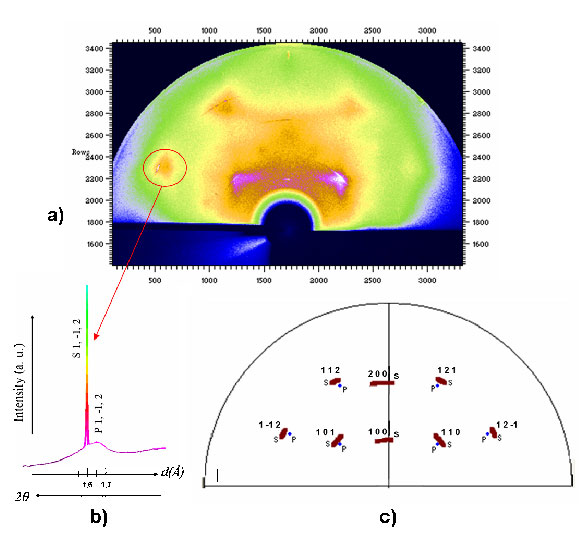

In order to determine if the structural phase of the deposited nanostructures was perovskite or not and to understand the crystallographic relationship to the substrate, grazing incidence x-ray synchrotron radiation scattering measurements were performed using an area detector at SSRL Beam Line 11-3. An area detector has scarcely been used in the analysis of ferroelectric isolated nanostructures or perovskite thin and ultrathin films. The two-dimensional diffraction pattern obtained is shown in Figure 3a. It consists of sharp short arcs and some diffuse spots. Figure 3b shows a 1D (line scan) cut through a representative sharp-broad peak pair. The positions of the Sharp Debye arcs agree well with the diffraction maxima of SrTiO3. The strong texture of the measured the Debye arcs indicates that the SrTiO3 crystals were orientated with (001) poles approximately normal to the sample surface. The diffuse spots of Figure 3a always appear on the low angle side of the sharp SrTiO3 arcs. This indicates a crystal phase with larger lattice parameters than SrTiO3, but an identical crystal structure. These maxima fit to PbTiO3 perovskite reflections well. The orientation similarity of the substrate and the PbTiO3 phase indicates that the PbTiO3 nanostructures have grown epitaxially on to the SrTiO3 substrate. Further, from the semi-quantitative analysis of the broadening of the peaks assigned to PbTiO3, it is deduced that these structures have nanometric sizes, as previously observed from the topographic image of Figure 1, and that they are strained. Modeling of all the Debye arcs and broad spots maxima is depicted in Figure 3c. An angular width of ~10º for the Debye arcs is assumed in the simulations.

The results shown here make these oxide nanostructures attractive for applications in nanoelectronic devices, pointing to the proposed fabrication strategy as a promising approach for the self-assembly of ferroelectric oxide nanostructures, which, in principle, is applicable not only to ferroelectric perovskites, but also to other functional multimetallic oxides.

M. L. Calzada, M. Torres, L. E. Fuentes-Cobas, A. Mehta, J. Ricote and L. Pardo. (2007) Ferroelectric self-assembled PbTiO3 perovskite nanostructures onto (100)SrTiO3 substrates from a novel microemulsion aided sol-gel preparation. Nanotechnology. 18: 375603.