Polymer solar cells represent a promising technology that enables solution processing of low-cost, flexible photovoltaic devices for clean energy applications through typical industrial mass production techniques, such as roll-to-roll printing. When fabricating these solar cells, the blend solution of an electron donor material and acceptor material is deposited and it dries to form the absorber layer, which exhibits the so-called “bulk heterojunction” structure (BHJ) resulting from phase separation and crystallization of the component materials. The final device performance is largely influenced by the structure of this BHJ layer and in the past decades a significant effort has been undertaken in order to understand and control its morphology.

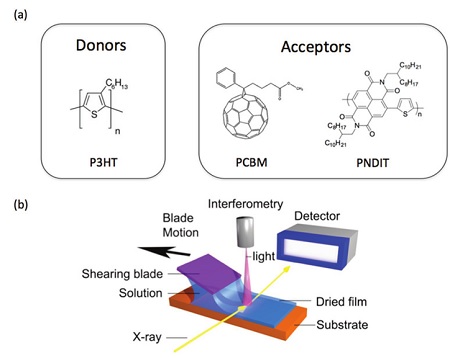

Figure 1. Chemical structures of materials used in this study (a) and a schematic illustration of the in-situ x-ray scattering technique (b).

Although most of the high performance acceptor materials are fullerene-based [1] (e.g. PCBM in Figure 1a), there is growing interest in replacing them with polymer acceptors to create all-polymer solar cells addressing the following considerations:

- Lower cost of polymer- than fullerene-based materials

- Broader sunlight absorbing spectrum of polymer acceptors

- Better thermal and mechanical stability of BHJ morphology of all-polymer BHJ layer

The performance of all-polymer solar cells still remains relatively low compared to their fullerene-based competitors. This is due to the formation of unfavorable morphologies in the thin absorber layers (around hundreds of nanometers) during solution processing. In order to develop high-performance all-polymer solar cells, better understanding of and control over BHJ morphology is highly desirable. Traditionally, film morphology characterizations are performed after dry films are fabricated under various processing conditions, which thus lack information on the structure development and evolution during these processes, and it can hamper materials and processing design towards optimized morphology.

In this work, with the solution casting system developed previously [2], in-situ real-time wide angle x-ray scattering technique is used to understand the molecular ordering (crystallization) process when the BHJ layers were processed (Figure 1b). Combined with optical interferometry and ex-situ hard and soft x-ray scattering characterizations, an in-depth understanding on the morphology evolution of all-polymer solar cells has been obtained and contrasted with polymer:fullerene based ones. This is the first report of real-time characterization of the BHJ structure of all-polymer solar cells during solution processing, which illuminates pathways to tackle the challenges faced by all-polymer solar cells, such as large unfavorable phase separation.

Figure 2. A schematic showing the comparison of the morphology development for the two blend systems investigated: (a) P3HT:PCBM blend; and (b) P3HT:PNDIT system.

These results successfully demonstrate that the high glass transition temperature (Tg) of fullerene and the tendency of the polymer to intermix with fullerene is critical in preventing large domain formation. The polymer acceptor used (PNDIT, Figure 1a) showed a Tg lower than room temperature, resulting crystallization of both donor and acceptor polymers in late stages of film drying (Figure 2). This consequently produced unfavorable large scale phase separation that negatively impacts charge extraction due to increased recombination before excitons reach interfaces between donor and acceptor materials to complete charge separation. This study suggests that control over crystallization behavior for the donor/acceptor is one of the critical challenges for high performance all-polymer solar cells. To reduce the large phase separation, the crystallization of the donor and the acceptor polymers needs to be suppressed.

[1] J. Zhao, Y. Li, G. Yang, K. Jiang, H. Lin, H. Ade, W. Ma and H. Yan, Nat. Energy, 1, 15027 (2016).

[2] X. Gu, J. Reinspach, B. J. Worfolk, Y. Diao, Y. Zhou, H. Yan, K. Gu, S. Mannsfeld, M. F. Toney and Z. Bao, ACS Appl. Mater. Interfaces 8, 1687 (2016).

X. Gu, H. Yan, T. Kurosawa, B. C. Schroeder, K. L. Gu, Y. Zhou, J. W. F. To, S. D. Oosterhout, V. Savikhin, F. Molina-Lopez, C. J. Tassone, S. C. B. Mannsfeld, C. Wang, M. F. Toney and Z. Bao, "Comparison of the Morphology Development of Polymer-Fullerene and Polymer-Polymer Solar Cells during Solution-shearing Blade Coating", Adv. Eng. Mater. (2016), DOI: 10.1002/aenm.201601225.