Speaker: Andrew Kiss, BNL

Program Description:

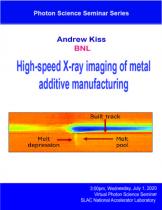

Additive manufacturing offers unique advantages over more traditional methods, such as the ability to produce new engineering designs, not possible with traditional techniques. One of the more popular methods of printing metals is known as laser powder bed fusion additive manufacturing. This method uses a powerful laser to melt a single layer of metal powder and build up the final part. To better understand how process parameters affect build quality, X‑rays are used as a new diagnostic tool to probe inside the part during the build process. Using high-speed radiography, the melt pool and vapor depression are directly imaged to observe the instability in the vapor depression and the formation of void defects. These observations provide valuable insight to understanding void formation and dynamics, as well as the challenges associated with removing voids in the final component.