January through March

2001

TABLE OF CONTENTS

A. Project Summary

1. Technical Progress

2. Cost Reporting

B. Detailed Reports

1.1 Magnets &

Supports

1.2 Vacuum System

1.3 Power Supplies

1.4 RF System

1.5 Instrumentation

& Controls

1.6 Cable Plant

1.8 Facilities

1.9 Installation

2.1 Accelerator

Physics

A. SPEAR 3 PROJECT SUMMARY

1. Technical Progress

The DOE Office of Science conducted a combined Semiannual/Quarterly Review

of the SPEAR3 Project on February 9, 2001. The review committee report

noted that "SPEAR 3 technical systems have continued to make good progress

in design and procurement. The committee did not find any major issues

and believe the project is working aggressively in making timely decisions

to correct identified concerns on design, schedule, and resource issues."

The DOE 1st Quarterly Report of FY 01 listed the Key Milestones

for the 2nd Quarter of FY 01. These were all achieved on schedule

except for the PSAD for which a draft was completed in March and is under

review.

Key Milestones Upcoming (next three months) Baseline Date

· Mini-Lehman Review 2/01

· Delivery of first production

magnets from IHEP 3/01

· BM1 & BM2 chamber Revere

copper delivery 3/01

· First lot of QFC chambers delivery

3/01

· Complete prototype fixed girder

3/01

· 1.2 MW klystron acceptance test

3/01

· Complete Preliminary Safety Assessment

Document (PSAD) 3/01

Revision 1 of the Project Execution Plan was approved by DOE in this Quarter.

This revision reflects the project changes of August 2000 which included

the baseline cost increases due to the extended schedule with project completion

in FY 03.

The first shipment of production magnets (9 Dipoles and 12 Quadrupoles)

left IHEP at the beginning of March and arrived at SLAC April 4. The magnets

are undergoing mechanical checks followed by fiducialization and magnetic

measurement checks. The magnets are shown in section B (1.1) where they

have been uncrated in PEP Interaction Hall #12. A second shipment of magnets

(3 Dipoles, 7 Quadrupoles, and 6 Sextupoles) left IHEP near the beginning

of April.

A prototype of one of the 3 magnet/vacuum support rafts (girder BM2)

for a standard cell was manufactured in March and delivered April 6. It

is planned that magnets and vacuum chambers will be installed on this girder

in the next quarter to check-out installation and alignment techniques.

This will be followed by the procurement of production units for all support

girders. A picture of the girder is shown in section B (1.1). The location

is Building 750 (Linear Collider Hall) where production assembly of the

technical components on the various support girders will take place.

For the Vacuum System, six sets of QFC machined halves were received

in February in preparation for e-beam welding. Tooling was designed and

fabricated to straighten the longer BM1 and BM2 chambers. The vacuum fabrication

facilities were prepared. All parts required to complete a BM2 chamber

were completed together with associated e-beam welder tooling. Unfortunately,

the e-beam welder required extensive cleaning in late March delaying chamber

production by approximately 3 weeks. The current plan is to complete the

prototype BM2 chamber in April for assembly with magnets in the first BM2

raft. QFC production will then proceed with production rate of approximately

1 unit/week. Two shift operation of e-beam welder is planned for April

23 to regain schedule loss.

All twenty bulk power supplies for corrector magnets have been received

and tested. The induction kicker supply is nearing completion. Following

a no-bid response, the main dipole supply will be build in-house following

the PEP-II design. Intermediate supply specifications are in progress.

The production of the main RF system components is proceeding well.

The 1.2 MW klystron was completed within the twelve months delivery time

and successfully tested in early March to 1.3 MW. The tube arrived at SLAC

April 9. Further testing awaits the availability of a PEP-II power supply.

The 4 RF cavities are in production with scheduled delivery in late CY

01. While the cavities are approximately 2 months late from the contract

schedule, they are near 1.5 years ahead of schedule for their planned installation.

The major part of the West straight section shielding was completed

in the FY 00 shutdown. Final connections to the existing shielding together

with the addition of new roof blocks over the entire straight section (required

for 500 mA) will take place in the regular FY 01 shutdown. This makes possible

the completion of the new RF system enclosure with installation of the

new klystron, associated components, and the waveguide system from the

klystron to the top of the west straight section shielding.

Work by the Instrumentation and Control group has continued to focus

on the detailed specifications and design of the computer control system

including the fast digital power supply controller, the BPM processor,

the orbit feedback systems, and the machine protection system. Various

control modules are in phases of design, fabrication, and testing.

Design of the cable tray system was the dominant activity in the Cable

Plant area. The conceptual designs, and many of the details, are well defined.

Unresolved issues center on upgrading the East-West elevated cable trays,

and integration of cable tray installation into scheduled yearly maintenance

periods. Additionally, management of the Cable Plant has shifted to the

SLAC Controls Department, with a concomitant increase in the level and

expertise of staffing.

As mentioned in previous reports, in order to achieve a final installation

schedule of 6 months, many modifications must be done in the normal shutdowns

prior to FY 03. In the last 3 months, the engineering and design drawings

and specifications have been completed for the shielding modification in

the WEST Straight section. The contract for this work will be out for bid

in April 2001. Similar work for the EAST Straight section will take place

in FY 02. This work is necessary for the shielding required for the higher

beam currents of SPEAR 3.

Also, the Accelerator Physics Group has made good progress toward specifying

corrector and kicker magnet performance, performing tracking studies, and

developing software for orbit control. Efforts have included specifying

locations and operational parameters of diagnostic components, and studying

mis-steering through matching cell lattice sections. Work has also included

girder vibrational modeling, beam dump specifications for radiation protection,

and studies of electron beam losses to implement radiation protection.

Work continues on the near term Radiation Physics objectives that will

have an effect on this years shutdown, as well as long term goals to comprehensively

assess all shielding and design parameters. Ongoing work includes defining

what additional shielding may be required for the new "C" shaped dipole

magnets and minimum thickness of roof shielding for areas around the ring.

A preliminary result (February 2001) indicates that no additional shielding

is required for the dipoles and that 12 inches concrete roof shielding

is adequate except in special locations which are currently specified for

SPEAR 2.

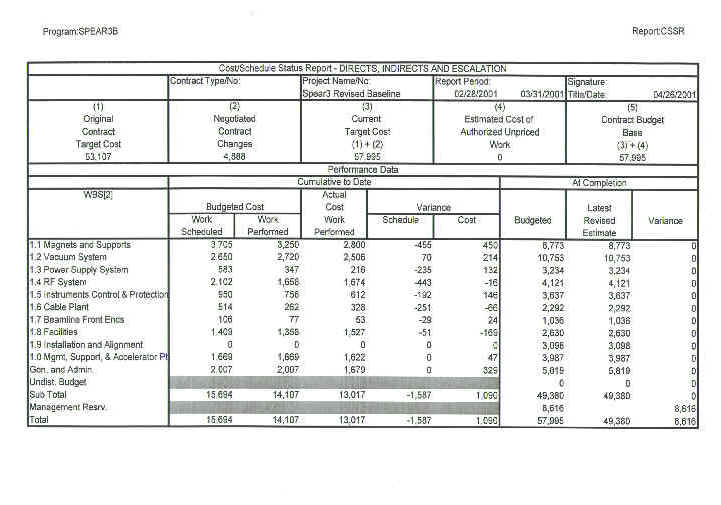

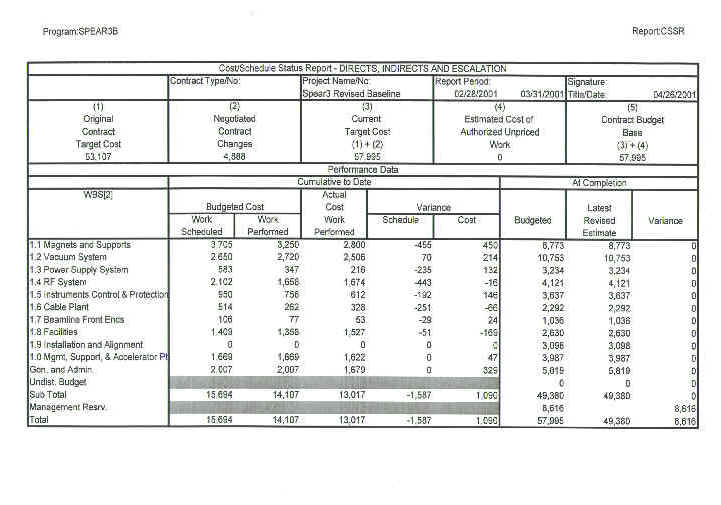

2. Cost Reporting

Approved DOE funding of 8M$ was received November 2000 with additional

funding of 2M$ this quarter bringing the total to 10M$ for this fiscal

year. NIH funding of 28M$ was received in FY 99 and FY 00 as indicated

in Fig. A1.

The total project costs and commitments through March of this quarter

are summarized in Table A1. The integrated costs and commitments per month

are given in Fig. A1.

Table A1

Project Costs through March 2001

(K$)

|

|

|

Direct Plus

|

|

|

Direct

|

Indirect

|

|

Costs |

11,339

|

13,019

|

|

Commitments |

2,230

|

2,420

|

|

Total |

13,569

|

15,439

|

Table A2 provides the project performance data with associated cost

and schedule variances at WBS Level 2. Monthly plots of this data for FY

2001 are provided in Figure A2 together with BCWS projections through September

2001.

Fig. A1

Table

A2

Fig. A2

B. Detailed Reports

1.1 Magnets

and Supports

Support System

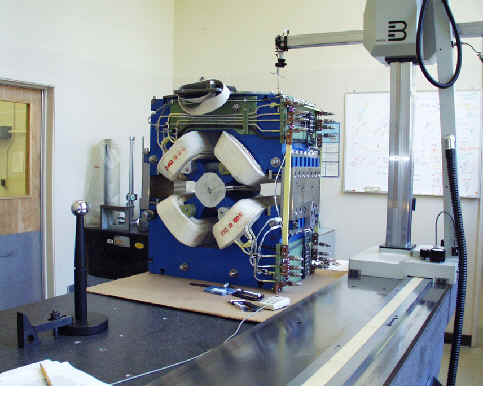

We have designed and received a prototype steel girder for the BM2 portion

of the standard cell. This girder will be mounted in an identical fashion

as the mounting scheme for the SPEAR3 ring installation. We hope to learn

pre-assembly and installation techniques as the magnets are installed and

aligned onto the girder over the next quarter. Orders for the production

steel girders are expected to go out next quarter.

BM2 prototype steel girder

Vibration tests on the prototype Sextupole and Quadrupole indicated

that the bottom brackets on both magnets need to increase in stiffness

to keep the first frequency above ~15 Hz. New brackets have been designed

and fabricated, and subsequent tests have proven the design adequacy for

the production magnets. Orders for production support hardware and struts

are expected next quarter.

Magnets

All parties signed updated versions of Attachment #1, 2 and 3 in early

January 2001. These documents incorporated new delivery dates and payment

schedules. Addendum #1 to the ICA, which tracked the current cost changes,

was signed along with Attachment #5 for the Horizontal & Vertical (H/V)

Corrector production. The H/V Corrector magnets represent the final magnet

order through IHEP for the SPEAR3 project. All magnets are scheduled to

be complete and delivered to SLAC by June 2002.

Nanyang Li, SPEAR3 magnet engineer, traveled to IHEP to review the production

magnets prior to the scheduled shipment to SLAC at the end of February.

This visit was highly successful as several items were found and corrected

before the magnets were crated and installed into the shipping containers.

The first shipments of production magnets arrived at SLAC on April 2nd

and were off loaded in PEP Interaction Region 12. These magnets are in

the process of mechanical and electrical checkouts after which they will

be sent to magnetic measurements and alignment.

First shipment of production magnets from IHEP being uncrated in IR12

Magnetic measurements

We have completed the magnetic measurements of the three prototype magnets

and they have received alignment data established to the fiducial stands

that have been welded to the magnet cores. This will be the standard procedure

used for the production magnets.

It is anticipated that approximately 20-25% of the production Quadrupoles

and Sextupoles will be magnetically measured, while 100% will be fiducialized.

For the Gradient Dipole, the fiducialization is incorporated with the magnetic

measurement hardware and therefore 100% of these magnets will be measured.

34Q Quadrupole in CMM lab to receive alignment data to fudicials

Corrector Magnets

IHEP has sent, and SLAC has reviewed the first set of H/V Corrector

detail drawings. IHEP will incorporate the changes and suggestions made

by SLAC and final drawings are expected early next quarter. Seventy-five

(75) magnets will be fabricated for the SPEAR3 project. The prototype H/V

Corrector magnet shipping schedule is August 2001.

1.2 Vacuum System

The engineering efforts during the past quarter included the following,

· Procure replacement copper

for the standard girder chamber.

· Procure and fabricate production

piece parts and sub-assemblies for the QFC chambers.

· Build tooling to straighten the

large BM-1 and BM-2 chambers.

· Establish production workflow and

travelers for the standard girder chambers.

· Prepare and layout the vacuum fabrication

facility.

· Inspect and destructively test the

Beam Position Monitors (BPMs).

· Assemble and develop the weld programs

for the BM-2 chamber.

· Develop the SLM mirror design requirements

and preliminary optics layout.

· Complete fabrication of prototype

BM2 vacuum supports.

· Complete the production Standard

Girder Support detail drawings.

· Fabricate the injection kicker prototype

magnet/chamber.

Standard Girder Chambers

QFC Standard and Matching Chambers

The first lot of production QFC chamber halves was delivered ahead of

schedule. Six sets of QFC halves were received in February. The plates

were inspected and met their design tolerances. During this quarter the

matching lattice was modified to use the same lattice as the QFC standard

cell. This was a key decision because it enables us to use the same vacuum

chamber and supports for both the standard and the matching, thus reducing

non-recurring engineering costs. The production order for the QFC piece

parts were increased including the machined halves. The remainder of the

QFC machined halves for the standard cell, as well as the additional plates

for the matching cell will be delivered in the beginning of April 01.

Significant progress was made on the procurement and fabrication of

the QFC piece parts this quarter. All the parts are on order and partial

shipments or full shipments have been received.

Also, production of the H2 absorber piece parts is near completion.

All the piece parts except for the GlidCop hot plate are complete including

the sub-assembly brazements. Initial manufacturing estimates indicate that

the piece parts are ahead of schedule and on budget. The following figures

show the machining of the H2 hot plate and some of the completed parts.

Production brazing of the absorbers will begin in April.

Absorber Machining Hot Plates

H2 Hot Plate NC Machining

BM-1 and BM-2 Standard Chambers

The purchase order for the replacement copper was placed in the beginning

of January and the first lot of copper was shipped at the end of March

on schedule. The plates will reach the machining vendor during the first

week of April. The first lot of BM-1 halves is due this summer. Tests to

verify that the copper meets our technical needs will be done early next

quarter.

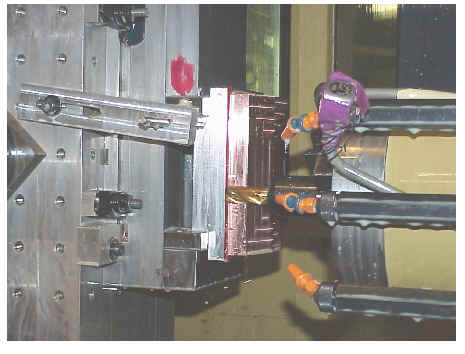

Work has continued on completing the first article BM-1 and BM-2 chambers.

The cooling bar welds on the BM-2 chamber was completed. A straightening

fixture for the long halves with cooling bars was designed and built and

the BM-2 halves were straightened and assembled in the box weld tooling.

An inspection device was designed and fabricated to measure the profile

of the slot. This is the critical dimension for the chamber to prevent

high power synchrotron radiation from striking the slot during a beam mis-steer.

It is difficult to inspect the profile of the slot once the chamber is

assembled, therefore a tool utilizing spherically mounted retroreflectors

(SMRs) and a laser tracker was developed. This tool slides through the

inside of the chamber and the laser tracker records the location of the

SMRs. Initial measurements show that the BM-2 chamber slot assembled and

partially tacked in the box weld tooling is within the specified profile

tolerance band and the nominal slot height is exactly the design value

of 13 mm. Similar results were found for the first two production QFC chambers.

Production programming for the tacking and the box weld sequences are underway.

The first BM-2 chamber will be complete in the beginning of May. The following

figures show the flange end brazement, the H1 absorber and the electron

beam weld programming for the BM-2 chamber.

BM-2 Flange End Brazement

H1 Hot Plate Machining

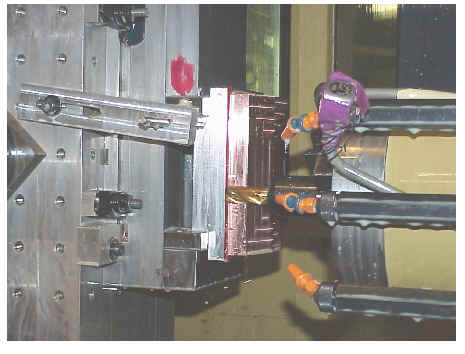

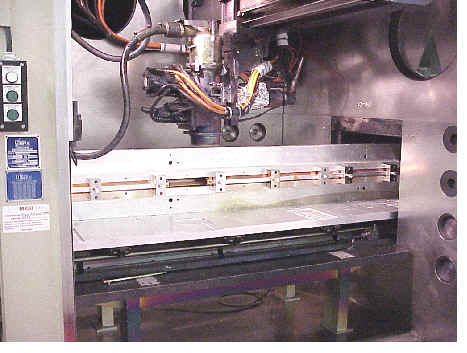

BM-2 Electron Beam Weld Programming

BM-2 Chamber

Manufacturing Standard Girder Chamber

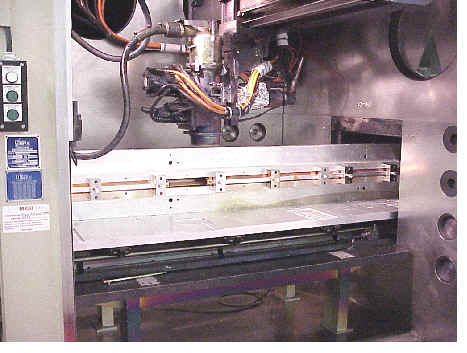

Significant progress has been made in preparing our vacuum assembly

building for production. Two large clean rooms have been reserved for SPEAR3

work and the fabrication of a temporary clean room is underway. This temporary

clean room will be an extension of the two large clean rooms and will be

used for the clean straightening of the chambers halves. Also, the electron

beam welder was successfully used to produce hundreds of chambers for PEP-II,

and will be thoroughly cleaned along with some machine maintenance in April.

Also, effort has been put toward the production planning and workflow

for the girder chambers. Travelers, data sheets and other documentation

for the QFC chambers are being reviewed and modified and will be ready

for full production by the beginning of May when the QFC chambers move

into the production phase. The production goal is to produce at least one

QFC chamber a week completing the standard girder QFC chambers by the end

of July 01.

Also, in late April we will obtain an additional electron beam welder

operator, as well as additional programming support. These personnel provide

secondary support when required to maintain our production schedule.

Standard Girder Vacuum Supports

The production detail drawings for the BM-1, BM-2 and QFC standard girder

vacuum supports were completed this quarter. Preliminary estimates for

the production supports were obtained and were within the engineering estimates

presented at the final design review. The production order is pending the

assembly of the prototype BM-2 girder, as well as the matching chamber

design. Also, the prototype BM-2 vacuum chamber supports were completed

this quarter.

BM-2 Prototype Vacuum Chamber Supports

Injection System

The injection kicker prototype piece parts arrived this quarter and

assembly is near completion. The 1.2 meter long K1/K3 prototype electrical

testing will begin in May. Also higher order mode testing is scheduled

for June followed by more electrical tests using the production modulators

and cables.

Injection Kicker

A preliminary design review for the septum chamber was held in January

and the action items from that review have been addressed. The final design

review is pending the final acceptance of the magnet design and manufacturing

tests for the chamber. The thin stainless steel inner wall is being prototype

to provide manufacturing and tolerance details. Also, studies on the potential

of beam loss into the thin inner wall are being studied. Initial physics

simulations show that during a beam abort the majority of the beam energy

is lost in areas of high dispersion. Therefore, only a small fraction of

energy will be lost to the septum. A fixed collimator will be added into

the QFC chamber at girder 16 to increase the probability that the energy

will be lost at this location.

Diagnostic System

Significant progress was made on the synchrotron light monitor (SLM)

this quarter. Many decisions regarding the optics and physics requirements

were made. The optics and mechanical layout of the SLM system was completed.

Once the major optics requirements were established the primary mirror

dimensions were defined. Preliminary drawings of the primary mirror along

with its mounting and actuating devices were also completed. A conceptual

design review is scheduled for the end of next quarter. Also during the

next few months a preliminary polishing specification will be developed

to obtain budgetary quotations for the fabrication and polishing of the

primary mirror.

1.3 Power Supplies

Dipole Power Supply

As reported in the last quarterly report the plan is to use a bulk power

supply purchased from industry and 4 PEP II-style modules, built at SSRL,

to make a 930 kW dipole magnet power supply.

Each of the 4 PEP II-style modules must provide 600V, 400A, 240 kW of

output. Since the last report, the engineering analysis and testing of

a PEP II-style chopper module to satisfy SPEAR 3 needs has gone well and

met all expectations. The PEP II module has been tested at 600 V and 400

A. All the component voltages, currents and temperatures that have been

measured are well within their ratings. It must be pointed out, however,

that the 600 V and 400 A goals have not been simultaneously achieved, due

to bulk power supply and load limitations. To work around this, the plan

is to move the test chopper module to Building 140 at the beginning of

the SSRL 2001 summer shutdown. At that time the White Circuit Bias Power

Supply will serve as a bulk power supply and the Bias magnets will serve

as an inductive 600 V, 400 A load. All indications to date point to a successful

full-load test without modification of the module. However, if problems

do arise during the test, they will be analyzed and corrected.

After the 600 V, 400 A ratings are successfully demonstrated, all the

parts needed to build 4 modules will be released for fabrication. At the

present time preparations are being made to purchase parts for the dipole

system components that are independent of the power test. Examples are

the power supply controllers, module chassis parts, transductors, etc.

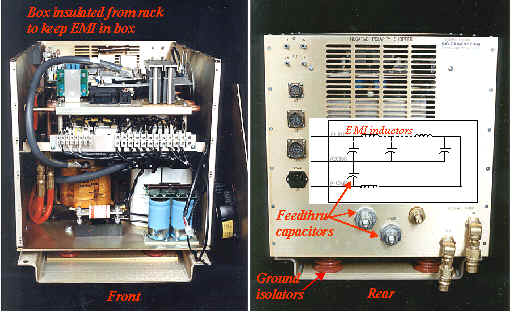

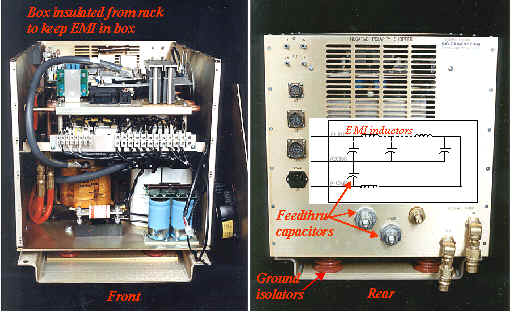

Below are some pictures of PEP II chopper equipment that will be replicated

for the SPEAR 3 Dipole Power System.

Dipole Bulk Power Supply and Some Installed Modules

Front and Rear Views of PEP II-Chopper Modules

Dipole Power Transformer

Neeltran has resubmitted the Dipole Power Transformer electrical and

mechanical drawings, incorporating SSRLs previous comments. The drawings

were reviewed by interdisciplinary SSRL members and found acceptable. The

transformer was released for fabrication and is expected onsite in June

2001.

Large Power Supplies

There are 6 large power supplies needed for SPEAR 3. These are freestanding

power supplies with output ratings greater than 35 kW. The power supply

service and ratings are tabulated below.

| Service |

Volts |

Amperes |

Kilowatts |

Cooling |

| SD |

600 |

225 |

135 |

Air/water |

| SF |

600 |

225 |

135 |

Air/water |

| QD |

700 |

100 |

70 |

Air |

| QF |

700 |

100 |

70 |

Air |

| QFC |

700 |

100 |

70 |

Air |

| QFC |

700 |

100 |

70 |

Air |

A design review for these power systems was held on March 7, 2001. Since

then, the review comments have been resolved, the technical specification

approved, and a purchase requisition written. The purchase requisition

is presently in the approval cycle for issuance of a request for proposal.

Bipolar Power Supplies

Testing of the prototype MCOR30 fast corrector bipolar power supply

was successful. A preliminary power supply specification sheet is available,

based on test results of the prototype. The bipolar power supplies are

now in the pre-production phase. The plan is to build an operational full

crate of 8 power supplies by late May. Bids for the final production run

and product support will be solicited during the next reporting period.

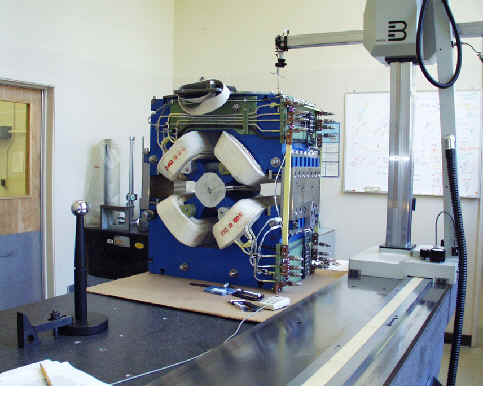

MCOR30 Crate With The Prototype Bipolar Power Supply

Pulsed Power Supplies

Kicker Pulsers

A four-stack version of the SPEAR 3 kicker pulser has been built and

is now in high voltage testing in the Power Conversion Department (PCD).

Below are photos of the prototype, and output current waveforms for a 1250

V charge. Higher charge voltages were not tested because some high voltage

arcing was evident from the IGBT driver board to the core assembly. Rounding

the corners on the core assembly and having a three-layer board made will

correct this problem. In the new driver board, high voltage will be contained

within in the middle layer.

Photo Of The 4-Stack Prototype Kicker Pulser

Prototype Kicker Pulser Output Current At 1250 V Charge

A layout for the electronic enclosure for the modulator core assembly

and board has started. PCD will have custom enclosures built that are based

on the standard SLAC design, but adjusted slightly for the height of the

core assembly.

Design of a prototype trigger interface board is complete.

Several minor changes have been made to the mechanical design of the

core assembly, to eliminate a propensity for high voltage arcing, poor

connections to the load resistor, and to reduce difficulty in aligning

the core stacks. The cases will now be 0.25 inches taller in order to provide

additional spacing between the drive boards and corners will be rounded

where the high voltage is close. In addition, dowel pins will be added

to the cases for easier alignment of the cores. The design of a more rigid

connection of the high voltage flange to the resistor load has been completed.

Until now, all testing has been done using RG-58 cable, which should

be good up to about 5 kV. The actual 22.5 W

, high voltage cable that will be installed in SPEAR will be sent to the

cable shop to be cut to length within the next week.

Precision Power Supply Controllers

The prototype BitBus precision power supply controller shown in the

figure below was built for PEP II and was borrowed from the SLAC Power

Conversion Department for test of a VME to BitBus adapter purchased by

the SSRL Instrumentation and Controls (I & C) Group. I & C have

reported initial success in having the adapter communicate with the BitBus

precision controller. Upon completion of successful testing, the precision

BitBus controllers will be released for fabrication during the next reporting

period.

Prototype Precision BitBus Power Supply Controller

Magnet Testing

Several dipole and quadrupole magnets have arrived from Beijing. These

are being electrically tested as they arrive. For each magnet the tests

consist of high potential testing and DC resistance measurements of the

main coils, trim windings and Klixon thermostats and B-field polarity measurements

at each pole.

1.4 RF System

Cavities

During a site visit to Accel Instrumentation in Germany in March 2001,

progress on the fabrication of 4 RF cavities was checked. A six weeks delay

caused by the qualification of the electro-forming process had not been

made up and threatened to delay final delivery. By choosing to do some

work at an outside sub-contractor, the progress will be speeded up. The

sub-contractor was visited and found to be very capable to perform the

work. Electro-forming is completed on all four cavities and cavity ports

are now being machined at the sub-contractor.

Fabrication of cavity accessories at SLAC like ceramic windows and higher

order mode loads is making rapid progress. All twelve high order mode loads

are completed. The ceramic windows had a faulty first braze test, indicating

a loss of the know-how at an external vendor. A first successful braze

was done in house at SLAC. Other components like tuners and coupling network

are 95% complete.

Klystron

The 1.2 MW klystron was ordered March 17, 2000 from Marconi Applied

Technologies with a 12 months delivery time. The successful acceptance

test at Marconi was witnessed March 8, 2001 and the klystron has since

arrived at SLAC in good condition.

Low-level RF

The Low-level RF System design modifications are in process at the new

Electronics & Software Engineering Department at SLAC.

1.5 Instrumentation

and Control Systems

Progress in design of instrumentation and control systems for the SPEAR

3 project continued, and some components were received.

Computer Control System

For computer control of the SPEAR3 main and intermediate power supplies,

the communication between a new commercial VME Bitbus interface and the

PEP2 Bitbus power supply controller (which will be used for SPEAR3) has

been successfully tested.

Some steps to finalize the design of the SPEAR3 corrector supply controls

were made. It looks like we are going to be able to use a commercial VME

CPU module in each corrector crate and have a serial digital communication

between this crate controller and each MCOR30 module. If a commercially

available CPU module can be used, the design and production will be simplified.

Details will be decided in a review in the second quarter 2001. Also, for

the MCOR30 design, several components (ADCs, DACs and multiplexers) have

been evaluated and successfully tested and characterized.

Software was written to test and characterize the Echotek digital receiver

modules which will be used to process the BPM signal data. Driver software

for VxWorks to handle these VME modules is now available.

Beam Monitoring Systems

Definition of Beam Position Monitor (BPM) electronics has focused onto

a two-system approach, in order to meet the diverse requirements of closed

orbit feedback and faster, first-turn response. High-performance closed

orbit feedback electronic modules are commercially available, and proposals

are being sought from the vendors. Electronics for faster response continue

to be developed within SSRL.

The BPM System and the Machine Protection System (MPS) are closely tied,

since button signals are shared by the two systems. A working decision,

that the signals be shared at the output of the BPM receiver modules, has

been made. The advantage is a reduction of modules, cables, crosstalk,

and simplified packaging. This information was presented to the commercial

suppliers for technical appraisal. The outcome will strongly affect the

system configuration, performance, and equipment layout, which will be

decided after a design review in May 2001.

BPM "buttons" were received from the commercial supplier and were tested.

Fifty buttons were tested according to the Acceptance Test Procedure, and

96% passed. Four randomly selected buttons are being life cycle tested

under extremely adverse conditions.

Digital IF (Intermediate Frequency) modules were received and extensively

tested. The full complement, 2 prototypes and 12 production modules, were

accepted from the supplier. One prototype is being evaluated in the SPEAR2

BPM system. Performance of the analog-to-digital converter has exceeded

expectations. An effort to improve the embedded software in the module

for the specific SPEAR3 applications is ongoing.

Quadrupole Modulation System

The design of the Quadrupole Modulation System was assigned to an engineer

within the SLAC Power Conversion Group. Management of this project will

be shifted from the SPEAR 3 I&C group to the Power Supply group (P.

Bellomo) during the next quarter.

Timing System

The PTS DDS-based signal generator that will serve as SPEAR 3 RF master

oscillator has been received and partially characterized. It looks like

its performance will exceed the requirements for SPEAR 3. Tests are continuing,

focusing on remote control functions.

Work on specifying the LO/Clock and Booster-SPEAR Phase-Locked Loop

systems has been on hold given that the new engineer assigned to the task

has had other higher priority responsibilities. The specification is planned

for completion during the next quarter.

Protection Systems

A decision was made to eliminate the Access Control Interlock search

areas in the East and West Pit buildings, making those areas accessible

when beam is stored in SPEAR The SPEAR 3 Personnel Protection System will

only control access to the SPEAR tunnel itself.

A decision was made to use commercial BPM electronics for the Orbit

Interlock System. Each BPM button will be sampled at a rate of 10 kHz,

and it will take 250 m s for the X and Y output

signals to reach 90% of their new value after a beam displacement.

The design of the SPEAR 3 vacuum controls and magnet cooling protection

system is in progress.

1.6 Cable Plant

Design of the cable tray system was again the dominant activity during

this last quarter. The details for the cable tray system are now well defined.

Formerly unresolved issues centered on the required upgrading of the new

East-West elevated cable tray supports, and their need to take on additional

potential loads. We believe that the additional load issues have now been

sufficiently addressed and we have proceeded with detailed design work.

Documentation for the new tray system supports outside of B117 and B118

has been submitted to the Earthquake Committee and approvals have been

received. Detailed documentation for the cable tray supports that will

be installed on the inside periphery in the SPEAR3 ring have also been

submitted to the Earthquake Committee and approvals have been received.

The existing underground cable ducts and covered trench will support

Klystron Power Supply cables originating from shelter B514 via a new concrete

underground duct bank extension. The decision on the tray OR duct approach

became the tray AND duct approach as indicated above.

Within Building 118, supports, which will suspend the trays from overhead

have been designed and are pending review and approval by the Earthquake

Committee. These supports are required to carry SPEAR3 cable loads and

a short LCW run to the water-cooled power supplies. This work can only

be done during the summer downtime and we have made the design and bid

package one of the highest priorities. The contract package to install

trays and/or supports in B118, between East and West Pits and ring outer-wall

supports is nearly complete in preparation for the 2001 summer downtime.

Our cable tray support concrete footings and trenching/duct bank concrete

work are to be integrated into the overall concrete contract work already

planned for the pit areas. By doing so we eliminate potential conflicts

and hindrances to other concurrent activities. This work will also be completed

during the summer 2001 downtime. Documentation of the cable tray support

footings and trench/duct work has been supplied to Brian Choi for inclusion

in the main contract.

We have implemented several training meetings to familiarize the engineering

and coordination staff in the use of entry methods and requirements for

the CAPTAR (Cable Plant Tracking and Reporting) database. One of the primary

uses of CAPTAR is report generation. This reporting capability is the one

mechanism used at SLAC, in concert with detailed drawings, that enable

contractors to bid and install cable plant. The training in CAPTAR also

clarifies for the engineering staff what information MUST be known in order

to have cabling included in the FY02 installation work.

1.8 Facilities

The engineering and design drawings for the remaining cast-in-place concrete

shielding walls and the pre-cast roof shielding in West Straight Section

were completed in March of this Quarter. The engineering package for the

subcontract is at Contract Administration. The site-walk for this project

is scheduled on 4/30/01. The construction will start in July and be completed

at the beginning of September 2001. The major elements of the work include:

· Excavation, trenching,

fill, sub-grade, preparation and backfill for parking lot, concrete alcove

wall foundations and slab.

· Field survey location and verify

the footprint of the slab foundations, alcove walls, and key design points

as indicated on drawings.

· Demolish and deliver the existing

concrete and asphalt to Building 120 parking lot for disposal by the University.

· Provide reinforced concrete slabs,

footings and walls.

· Remove and re-locate existing concrete

shielding blocks as indicated on drawings. This work includes removing

all the existing seismic anchorages.

· Detail, fabricate, deliver shielding

blocks, off load at the delivery site and install in accordance with this

specification and subcontract drawings.

· Furnish and install all seismic

anchorage as specified on drawings.

· Reinstall supporting members, siding,

and install new flashing over new roof shielding blocks.

The engineering and design drawings for the tunnel utilities modification

are 70% complete. The installation of the utilities has been postponed

until 2002 shutdown in order to minimize the shutdown length periods. Only

minor utility modifications will take place in West Pit in 2001 shutdown

to facilitate the shielding work. The various accelerator maintenance groups

will further define the lighting placement and requirements of the AC distribution

before the design is finalized.

1.9 Installation

This WBS category includes only the final major installation period planned

for FY 03. The work includes removal of all SPEAR 2 technical systems,

the construction of new re-inforced concrete floors in the storage ring

tunnel and in the existing power supply building, the installation of SPEAR

3 technical systems together with power and signal cables, and final tests

of in-place technical systems and components.

The time duration goal for this final installation period is

six months. Some 38 pages of schedule details were provided for the July

2000 Lehman review without full optimization for multishift or weekend

operation. This will be addressed after we are assured that all activities

are defined and included.

The Installation Schedule is now undergoing updates and revisions. Line-by-line

review has taken place in the recent few weeks with the intent of identifying

areas where the overall project duration might be reduced. We have had

a detailed look at resource loading and no surprises have surfaced. Current

activities include the incorporation of schedule revisions resulting from

recent changes in sub-systems design and installation logistics.

2.1 Accelerator Physics

Summary

In the second quarter of FY2001, the accelerator physics group generated

beam loss estimates in SPEAR 3 for the radiation physics department, developed

Channel Access software for communication between application programs

and the on-line database, refined electron beam mis-steering specifications

and began developing detailed specifications for the synchrotron light

monitor.

Radiation Physics

SSRL radiation physics document ' Electron Beam Loss Estimates for SPEAR

3' (1997) was extensively revised to reflect Injector upgrades and engineering

details for SPEAR 3. Two of the main changes were to increase the injection

beam power from 2 W to 4 W and introduce a fixed collimator to intercept

much of the electron beam power load in the SPEAR tunnel (see 'Fixed Collimator'

below). The revised document, (SSRL-ENG-NOTE 371M), was reviewed by the

SLAC Radiation Safety Committee with minor revisions suggested. In particular,

the power load estimate on the fixed collimator was increased from 50%

to 100% of total accumulated charge to increase shielding requirements.

The shielding philosophy at SLAC is 'ALARA' (As-Low-As-Reasonably-Achievable).

The anticipated pattern of electron beam loss through the SSRL accelerator

chain and within the SPEAR 3 tunnel is shown in the following two figures.

Electron beam loss channels for SSRL accelerator complex

Electron beam loss channels in SPEAR 3 Tunnel

Fixed Collimator for Radiation Protection

In the last reporting period we introduced a 'leading edge' mask in

the RF straight section to protect the injection septum from stray charge

lost during injection. Further analysis of particle loss showed the need

for a second fixed collimator at a location of high dispersion, in particular,

high non-linear dispersion. The energy collimator will be located in the

QFC chamber of Cell 16 with an inside radius of 30 mm. The collimator

will intercept particles lost from the 'RF bucket' which tend to spiral

inward to the center of the ring at high dispersion points. As the particle

energy deviation exceeds 4-5%, the dispersion becomes a non-linear function

of energy and peaks at eight locations throughout the storage ring. One

of these locations, Cell 16, has been chosen as a location for the fixed

collimator mask. In this capacity, the mask is expected to intercept up

to 100% of the 1.2 kJ electron beam during RF beam abort at 500 mA/3GeV

and most of the beam lost to Touschek or inelestic scattering. Cell 16

is also an optimum location since the concrete shielding is up to 4 ft

thick, user occupancy is minimum, and the priority for future beam lines

is low.

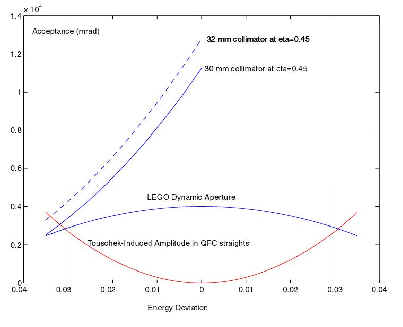

Energy Acceptance Calculations

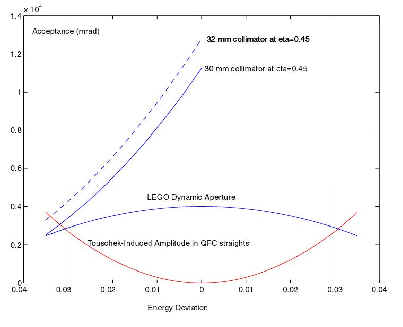

Analytical calculations were made for physical aperture, rf aperture,

and dynamic aperture as a function of energy deviation (after D. Robin,

et al, Arcidosso, 1998). Induced betatron induced amplitudes following

a Touschek event can be shown on the same plot. The intercept of induced-amplitude

with limiting

apertures (physical, dynamic) indicates the energy aperture.

For 3.2 MV rf, the bucket size is ~3% at 3 GeV (see figure). The energy-dependent

dynamic aperture curve also intercepts the induced-amplitude curve at about

3% for linear optics. An aperture reduction of about 20% occurs for non-linear

optics (off-energy optical functions and dispersion orbit). Based on these

data, the intercept of induced betatron amplitude with an aperture introduced

by the fixed QFC collimator located at 30 mm is on the order of delta=3.5%.

Accelerator Simulator

The Accelerator Toolbox (AT) software has been released to the accelerator

physics community and is now in use or being evaluated for use at CAMD,

LBL, SLAC, SRC, SSRL and the SNS. The software was also used to teach particle-transport

'mapping' techniques at the USPAS accelerator school in Austin, Tx this

quarter. A 37 page report 'Accelerator Toolbox for MATLAB' (SLAC-PUB-8732)

was issued to document the code. To fully improve communication between

AT and the SPEAR 3 control computer, the 'Simple Channel Access' software

(SCA) adopted from LBL was replaced with a direct 'Channel Access' (CA)

connection. The new software eliminates the SCA layer of code between the

user and CA (direct CA calls now), and fulfills an important need for SSRL

and other laboratories using both MATLAB and the EPICS control system.

Application Programs

The ORBIT application program continued to undergo on-line testing which

resulted in both code interface and underlying code modifications. In particular,

ability to measure corrector-to-electron BPM and corrector-to-photon BPM

responses was added and tested on SPEAR 2. Several eight-hour orbit feedback

tests were made using the measured response matrix to demonstrate code

stability. The graphical user interface was also changed to permit 'slider'

control of orbit corrections, add help facilities and improve user interactions.

The new version of database access routines using direct Channel Access

calls will be installed and tested in coming months.

Electron Beam Mis-Steering

Analysis was carried out to evaluate electron beam mis-steering from

dipole magnets with orbit interlocks active. Referring to SSRL Engineering

Note M344, the maximum vertical mis-steering amplitude in dipoles with

interlocks on is 26 mm-mrad. With interlocks on, the global orbit distortion

has an emittance amplitude limit of 1.15 mm-mrad (limited by a 2.45 mm

x 0.49 mrad trip level in the ID interlocks). Computing the mis-steer amplitude

with a local orbit distortion amplitude of 4.84 mm-mrad and a global amplitude

of 1.15 mm-mrad with interlocks on, the net mis-steer limit is 11 mm-mrad.

In order to protect sensitive vacuum chamber components, masking must be

provided to intercept vertically mis-steered electron beam in the dipoles

to 11 mm-mrad.

Synchrotron Light Monitor

A concrete drilling company was contacted to comment on the feasibility

of drilling a SLM radiation exit port through the shielding wall. The company

reported no fundamental problems but the exit port must go between rebar

tie points to maintain structural integrity of the wall.

With the help of photon beam line engineers, the preliminary front-end

optics for the SLM has been designed. Exiting from magnet 15BM2, the radiation

will pass through the 15S16 insertion device exit port. A 'cold finger'

(cooled copper bar) will intercept +/- 0.6 mrad vertical radiation from

the core of the beam to reduce total beam power. The total vertical aperture

will be +/- 3.0-3.5 mrad and the horizontal aperture will be on the order

of +/- 3.0 mrad. The M0 (first) mirror will be Si substrate to utilize

the low thermal expansion coefficient. Depending on the exact photon beam

energy range of interest (~200 nm) and reflectivities of each polarization,

a metallic surface coat may be required. 200 nm is desirable because off-the-shelf

optical components are available. The final m0 incidence angle still needs

to be specified.

A study of a reflective-optics (Schwarzchild mirror) configuration for

magnification and propagation into the SLM diagnostics room has begun with

design code Zemax. The optics code produces simulated images to indicate

effects of spherical aberrations. Diffraction effects due to the cold finger

shadow will be investigated. The beam source is 182 x 51 micron with 5

mrad curvature, 39 mm length and 98 micron sagitta. With the Schwarzchild

mirror configuration, the beam can be imaged directly onto the CCD camera,

and a splitter can be used to extract beam for streak camera applications.