|

Scaling of conventional silicon based metal-oxide-semiconductor (MOS)

transistors requires thinner and thinner SiO2 films. However, the

|

|

Figure 1: Intel 45 nm SRAM chip and IntelrCoreTM2 family processor.

Hafnium-based high-k dielectric materials are used in the fabrication of those

chips.

| |

|

increase of leakage current through thinner SiO2 films puts a

fundamental limit on the existing MOS technology. High dielectric constant

(high-k) materials are natural substitutes for

SiO2 as insulators because they can maintain sufficient thickness to

achieve desired capacitance. In fact, hafnium based high-k dielectric materials are already used by Intel in the

fabrication of the current generation of 45 nm SRAM chips and processors

(Figure 1).

The increasing need for higher speed and lower power consumptions has pushed

Si-based transistors to their performance limit. III-V compound semiconductors,

due to their high carrier mobility, are very promising in replacing Si as

substrates of semiconductor chips. Various combinations of

high-k dielectric

films on III-V substrates are being actively evaluated. However, sufficient

valence and conduction band discontinuities between the

high-k insulator and

the semiconductor substrate are necessary to act as barriers for both electron

and hole injection. Therefore, before a particular

high-k insulator is selected

for semiconductor chip it is very important to know the band offsets between it

and the semiconductor substrate.

|  |

|

Figure 2: TEM image of LaAlO3 film on

In0.53Ga0.47As with the schematic

band diagram. Numbers in parenthesis are measured or calculated in this study.

|

|

In this work, high-k dielectric LaAlO3

films on In0.53Ga0.47As substrates were grown at Intel

and studied at Stanford Synchrotron Radiation Lab (SSRL). As shown in figure 2,

only the band gap of the In0.53Ga0.47As substrate is

already known. To find out how the bands are aligned, we needed to establish

the valence band offset DEv and the band gap of the

amorphous LaAlO3 film, both of which were measured by photoelectron

spectroscopy at beam line 8-1 and beam line 10-1 of SSRL.

Valence band offset can be obtained by comparing the valence band maximum (VBM)

of LaAlO3 and In0.53Ga0.47As, as shown in

figure 3. However, because LaAlO3 is an insulator, positive charge will be

built up on the surface when photoelectrons are emitted. This positive charge

will cause the whole spectrum to shift. To correct this shift, a sample with

thin (1 nm) LaAlO3 film is prepared because we can collect both As

3d and Al 2p core levels from this sample. These two core levels are used as

references to align with the As 3d of the clean

|  |

|

Figure 3: Valence-band and core level spectra for a clean n-type

In0.53GaAs (001) sample (a and d), a sample with 15 nm-thick

amorphous LaAlO3 film (b and e), and a sample with 1 nm-thick

LaAlO3 film (c

and f). The spectra were measured with a photon energy of 140 eV.

|

| In0.53Ga0.47As sample

and the Al 2p of the sample with

thick (15 nm) LaAlO3 film, respectively. After the spectra are

properly aligned and the spectral shift caused by surface charging is

corrected, the valence band offset is determined as 3.1 eV.

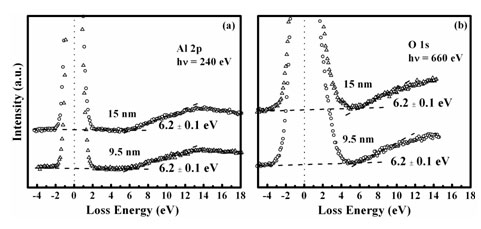

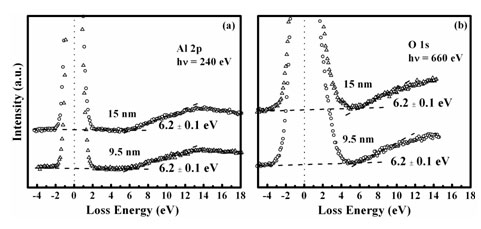

The band gap of LaAlO3 is traditionally determined by optical

measurement. However, the band gap of LaAlO3 film is generally

different from that of bulk LaAlO3. In addition, it is found that

band gaps of high-k dielectric films are also

significantly affected by film growth conditions. Therefore, we can not rely on

previously published LaAlO3 band gap data. In this work, we use the

energy loss features of Al 2p and O 1s core levels to measure the band gap, as

shown in figure 4. This energy loss feature creates a slope on the higher

binding energy side of the background. The energy difference between the onset

of the slope and the core level peak position is the band gap. Here, the band

gap of the LaAlO3 film is measured as 6.2 eV. Consequently, the

conduction band offset is calculated to be 2.35 eV. These measured and

calculated numbers are shown in parenthesis in figure 2.

|  |

|

Figure 4: Energy loss spectra of (a) Al 2p and (b) O 1s core levels for

9.5 and 15 nm-thick amorphous LaAlO3 films. The two curves in each

plot are offset along the intensity axis for clarity. The band gap was

determined by linear extrapolation, shown by the dashed lines.

|

|

The band offset measurements, in theory, can also be done using conventional

UPS and XPS instead of synchrotron sources. In reality, several problems with

conventional sources make it very difficult. For example, UPS can measure the

valence band, but lack of core level information makes it impossible to align

the spectra in order to correct the charging effect. For the band gap

measurement, the energy loss feature is very weak, and therefore, for a

reliable quantification it is necessary to have a very flat background and

narrow core level peak. In a conventional XPS system the photon energy is not

tunable and the spectral resolution is poorer, making it virtually impossible

to identify the onset of the slope caused by the energy loss feature.

Therefore, because of the high collimation and very high-resolution, coupled

with continuous tenability of the photon energy, XPS systems operating at

synchrotron sources are ideally suited to study the band offsets between thin

films and substrates.

Band gap and band offset measurements are not only very important for

addressing the viability of newer generation of semiconductor chip technology,

but they are also of vital importance in the study of materials used in solar

energy technologies, which are actively investigated in SSRL as well. The

techniques highlighted here pave the way for investigations of many

technologically important electronic devices.

Primary Citation

N. Goel, W. Tsai, C.M. Garner, Y. Sun, P. Pianetta, M. Warusawithana, D.G.

Schlom, H. Wen, C. Gaspe, J.C. Keay, et. al. (2007) Band offsets between

amorphous LaAlO3 and In0.53Ga0.47As. Applied

Physics Letters, 91, no.11, p.113515

|