Home Page

|

Prototype Focusing Element for the LCLS Warm Dense Matter ExperimentLLNL is developing focusing elements for the Warm Dense Matter experiment to be performed at the LCLS. This experiment studies the interesting properties of "warm dense matter", an energetic plasma at near-solid density. Thought to exist in the centers of large planets, the properties of this state of matter are important to astrophysics and relevant to the production of inertially confined fusion reactions. To create warm dense matter in the laboratory the 8 keV, 100 Ám diameter LCLS x-ray FEL beam will be focused on to a spot 2 to 10 Ám in diameter in the center of the sample of solid matter under study. The focusing element of choice for this experiment is a 200 Ám diameter "blazed phase lens" made of Carbon, which is capable of withstanding the full, unfocused, LCLS beam without sustaining damage.

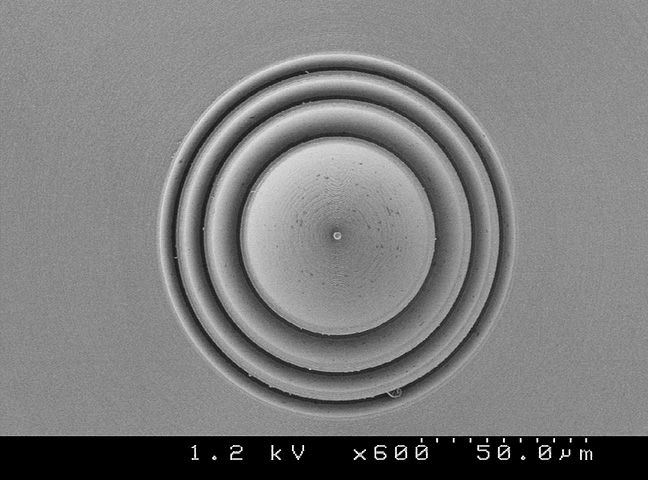

Figure 1: This photograph shows a 100 Ám diameter prototype of this lens made of Aluminum, which has nearly the same phase-changing optical constant as Carbon for 8 keV light.

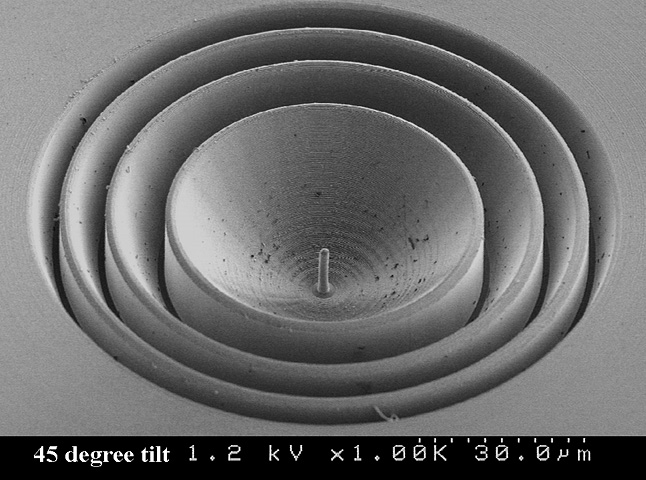

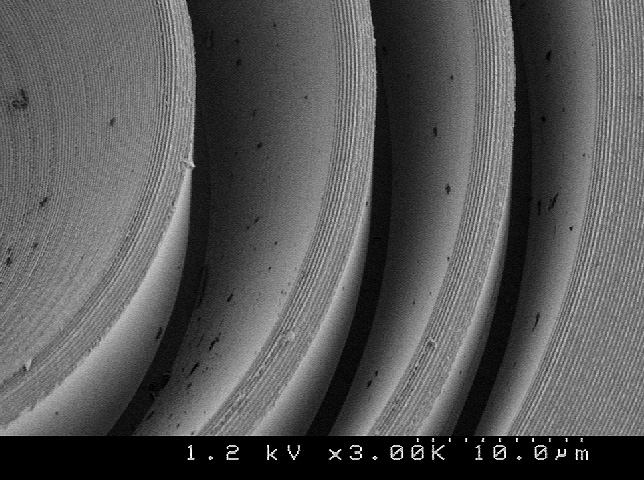

Figure 2: LLNL’s Precision Systems and Manufacturing Group developed a specially shaped, single crystal, diamond-turning tool to carve the lens pattern into the surface of a flat disk of pure Aluminum. Each groove is 18.7 Ám deep, which is the thickness in Aluminum where 8 keV x-rays acquire an extra 2 p radians of phase shift with respect to x-rays traveling the same distance in vacuum. The small pillar in the center is difficult to remove but has negligible effect on the performance of the lens. The carved disk was subsequently flipped over and thinned down from the back side to a final thickness of 79 Ám.

Figure 3: The lens profile changes the phase of the raw LCLS beam, converting it from an outgoing Gaussian beam whose waist is inside the undulator, to a converging Gaussian beam whose smaller waist is in the target foil. The required phase change as a function of radius is reset every 2 p radians and converted to a material thickness using the optical constants of Aluminum with respect to vacuum. Unlike conventional Fresnel zone plates, which only crudely approximate the needed phase profile, and as a result have a myriad of unwanted positive and negative foci, this lens imparts the correct phase shift across the entire wavefront (except at the rims of the grooves where the accuracy is limited by the finite size of the single point diamond tip.) LLNL expects to continue research into the manufacture of lenses of this type, and their testing at SSRL, with the goal of producing 200 Ám diameter Carbon lenses over the next two years.

Richard M. Bionta Physics and Technology Directorate Lawrence Livermore National Laboratory This work was performed under the auspices of the U. S. Department of Energy by Lawrence Livermore National Laboratory under contracts No. W-7405-Eng-48. |