Fluid catalytic cracking (FCC) is the refining process for converting large and/or heavy molecules of oil feedstock into smaller and lighter hydrocarbons, such as gasoline. The workhorse of the FCC process is a tiny catalyst particle of 50-150 µm diameter that consists of a complex mixture of amorphous silica-alumina, clay, and zeolite. An important factor in designing FCC catalyst particles is their pore-structure, which enables feedstock molecules to reach and enter the catalytically active particle domains and, after cracking, allows the product molecules to leave the catalyst. Any blockage of this pore structure is therefore detrimental in terms of catalyst efficiency.

Heavy metals, such as Fe, Ni, or V, that are present in the feedstock are known to accumulate in FCC particles and have negative effects on the conversion efficiency, summarized as ‘metal poisoning’. For example, it is known that Ni and V can decrease yield by catalyzing dehydrogenation of hydrocarbons present in the feedstock, leading to increased coking of the particle, which can lead to micro-pore plugging, while Fe is suspected to contaminate the particle, directly clogging pore space.

The design of improved, future catalysts therefore requires fundamental insight into the effects of metal poisoning and related changes in porosity and catalyst permeability which in turn demands for studies of catalyst structure and chemistry at multiple length scales: from the reactor (meters) down to the single particle level (nanometers).

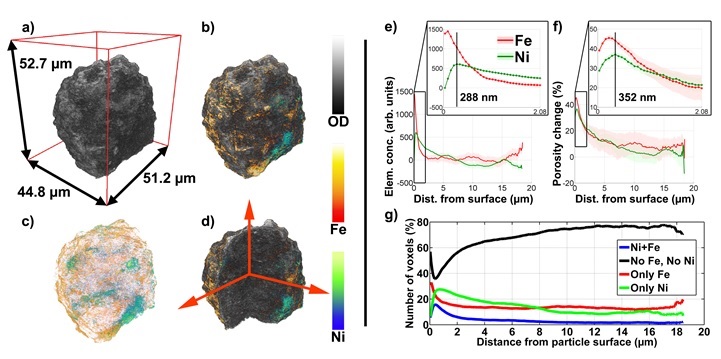

In this study, researchers from Utrecht University (Netherlands) and SSRL investigated a whole single equilibrium catalyst (E-cat) particle, i.e. a catalyst that had undergone several cycles of the FCC process, using transmission hard X-ray microscopy (TXM) at beamline 6-2C of SSRL. Measurements were performed to obtain 3D information about Fe and Ni relative concentration distributions as well as morphology, porosity, and permeability of the E-cat particle. Here the unique capability of the instrument installed at BL6-2C to stitch together multiple fields-of-view (FOV) of 30 x 30 μm2 to obtain an even larger FOV was essential to image in 3D and at high spatial resolution (64 x 64 x 64 nm3 voxel size) the whole catalyst of about 50 µm diameter (fig. 1, a-d). Three-dimensional relative elemental distributions of Fe and Ni were generated by tuning the X-ray energy across the respective X-ray absorption edges (differential contrast imaging), allowing for an investigation of the effects of metal accumulation on the pore structure and permeability of the catalyst particle (fig. 1, e-g).

The novel experimental method developed in this study allows scientists to achieve in 3D chemical/elemental sensitivity, while maintaining high spatial resolution over a large field of view. Specifically for this study, the quantitative evaluation of the elemental concentration/correlation as a function of distance from the catalyst particle surface revealed that both Fe and Ni contaminate the particle from the outside, following the pathway of entering feedstock molecules through the macro-pores of the catalyst. The metal deposition in the pore space of the particle was correlated with a decreased porosity and permeability in the near surface region highlighting the pore-clogging effect of both Fe and Ni. Based on these promising results further investigations of fresh and E-cat samples will be performed to further understand and fully examine the effects of metal accumulation in single FCC catalyst particles.

Figure 1. The left panel shows the 3D representations of the ~50 µm diameter FCC E-cat particle based on TXM mosaic computed tomography with a voxel size of 64 x 64 x 64 nm3. a) Optical density (OD) as recorded at 7060 eV. b) - d) Visualization of Fe (orange) and Ni (blue) 3D relative distributions obtained from differences of tomography data: 7160-7060 eV and 8400-8300 eV, respectively. d) Cut through the tomography data showing the inner structure of the particle. The right panel shows the quantitative evaluation of the elemental concentrations/correlations as a function of distance from the particle surface. (Copyright J. Am. Chem. Soc., 2015, doi:10.1021/ja511503d)

F. Meirer, D. T. Morris, S. Kalirai, Y. Liu, J. C. Andrews and B. M. Weckhuysen, "Mapping Metals Incorporation of a Whole Single Catalyst Particle Using Element Specific X-ray Nanotomography", J. Am. Chem. Soc. 137, 102 (2015), DOI: 10.1021/ja511503d.